Reverse polarity DC motor cyclic timer

- Thread starter dhruvpatel00764

- Start date

Scroll to continue with content

thanks @boostbuck . i want to know value of components if possible. I'm newbie here that's why asking.

Last edited:

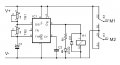

It appears from your photograph that the two trimpots are 2.2 Meg, but the other component values are hidden. If the circuit is supplied by 12V then R1 would be about 1K0. C2 around 1n0. C1 will be determined by the range of timing you require. D1 a 1N4007 it appears.

FYI I note an error in my sketch - pin 2 and 6 of the 555 should be connected for astable mode, per section 7.4.2 in this datasheet (which also has tables to help you determine value of C1).

FYI I note an error in my sketch - pin 2 and 6 of the 555 should be connected for astable mode, per section 7.4.2 in this datasheet (which also has tables to help you determine value of C1).

A Relay is a mechanical device, and is subject to wear,

and has a finite number of operations that it is designed to endure.

If this project is intended to run continuously,

it will eventually fail, or become intermittent,

especially if the Relay is not extremely over-specified for

the proposed Load that will be expected to withstand.

Reversing the polarity on a running Motor will cause a tremendous Current-Spike

which will quickly destroy the Relay's Contacts, and the Brushes inside the Motor.

More specific information is required regarding what this project is supposed to accomplish overall,

how reliable it must be,

the specifications of the Motor that will be switched,

exactly how long between reversals,

the mechanical-Load that the Motor is moving,

etc., etc., etc..

.

.

.

and has a finite number of operations that it is designed to endure.

If this project is intended to run continuously,

it will eventually fail, or become intermittent,

especially if the Relay is not extremely over-specified for

the proposed Load that will be expected to withstand.

Reversing the polarity on a running Motor will cause a tremendous Current-Spike

which will quickly destroy the Relay's Contacts, and the Brushes inside the Motor.

More specific information is required regarding what this project is supposed to accomplish overall,

how reliable it must be,

the specifications of the Motor that will be switched,

exactly how long between reversals,

the mechanical-Load that the Motor is moving,

etc., etc., etc..

.

.

.

thanks for help. just curious if i have to stop motor for let say 2-3 sec delay in between each cycle, can i do that with this circuit also?

i want to create rotating device using 755 motor,A Relay is a mechanical device, and is subject to wear,

and has a finite number of operations that it is designed to endure.

If this project is intended to run continuously,

it will eventually fail, or become intermittent,

especially if the Relay is not extremely over-specified for

the proposed Load that will be expected to withstand.

Reversing the polarity on a running Motor will cause a tremendous Current-Spike

which will quickly destroy the Relay's Contacts, and the Brushes inside the Motor.

More specific information is required regarding what this project is supposed to accomplish overall,

how reliable it must be,

the specifications of the Motor that will be switched,

exactly how long between reversals,

the mechanical-Load that the Motor is moving,

etc., etc., etc..

.

.

.

timing value in seconds : start>10 sec forward>2-3 sec delay>10 sec reverse>2-3 sec delay>start the cycle again.

in above pictures that i posted, there is two pots to make adjustment on forward and reverse time.

hope you understand, sorry for my bad english.

What is the "Locked-Rotor-Amps" of the 755-Motor at the Voltage that You intend to use ?

Please describe, in detail,

( pictures would be the best ),

the Mechanical-Load that the Motor will be turning.

Will the Motor be attached to ...............

a Gear-Box ?, a Fan/Propeller ?, Wheels on a small car ?, Belt and Pulleys ?

Does the Motor need to be stopped before hitting an object,

or reaching "end-of-travel" on a rail ?, or, is it driving a "Linear-Actuator" ?, or a "Screw" ?

ALL OF THE DETAILS ARE IMPORTANT,

for a project that will perform as expected, and have reliable-operation.

.

.

.

Please describe, in detail,

( pictures would be the best ),

the Mechanical-Load that the Motor will be turning.

Will the Motor be attached to ...............

a Gear-Box ?, a Fan/Propeller ?, Wheels on a small car ?, Belt and Pulleys ?

Does the Motor need to be stopped before hitting an object,

or reaching "end-of-travel" on a rail ?, or, is it driving a "Linear-Actuator" ?, or a "Screw" ?

ALL OF THE DETAILS ARE IMPORTANT,

for a project that will perform as expected, and have reliable-operation.

.

.

.

MisterBill2

- Joined Jan 23, 2018

- 19,601

The photo of the component side is so very poor and dark that nothing can be read or even seen clearly. And while the lifetime of relays is far from infinite, if the relay is used well within limits it should last for a long time.

i want to create like this on small scale. it consumes 20W of power. i would like to use with 12v power supply.What is the "Locked-Rotor-Amps" of the 755-Motor at the Voltage that You intend to use ?

Please describe, in detail,

( pictures would be the best ),

the Mechanical-Load that the Motor will be turning.

Will the Motor be attached to ...............

a Gear-Box ?, a Fan/Propeller ?, Wheels on a small car ?, Belt and Pulleys ?

Does the Motor need to be stopped before hitting an object,

or reaching "end-of-travel" on a rail ?, or, is it driving a "Linear-Actuator" ?, or a "Screw" ?

ALL OF THE DETAILS ARE IMPORTANT,

for a project that will perform as expected, and have reliable-operation.

.

.

.

MaxHeadRoom

- Joined Jul 18, 2013

- 28,851

The 755-Motor that You have chosen is a high-quality, very HIGH-RPM-Motor.

It would be a better plan to use a "Gear-Motor", with a much lower RPM-range,

probably less than ~1000-RPM @~12-Volts.

The Electronics part of the project is relatively easy, but not particularly cheap,

( probably around ~$30.oo USD )

.

.

.

It would be a better plan to use a "Gear-Motor", with a much lower RPM-range,

probably less than ~1000-RPM @~12-Volts.

The Electronics part of the project is relatively easy, but not particularly cheap,

( probably around ~$30.oo USD )

.

.

.

its manually controlled by swich and also module is from AliExpress so they don't ship to india. thank you by the way.This may do the trick for you, Aliexpress.

It has stop start PB's and pot for delay.

View attachment 321280

ok so if i will use simple gear motor. but can circuit sustain current that you have provided in diagram?The 755-Motor that You have chosen is a high-quality, very HIGH-RPM-Motor.

It would be a better plan to use a "Gear-Motor", with a much lower RPM-range,

probably less than ~1000-RPM @~12-Volts.

The Electronics part of the project is relatively easy, but not particularly cheap,

( probably around ~$30.oo USD )

.

.

.

Last edited:

I have not provided any Circuit suggestions yet,

because I needed more information about the equipment that will actually be used in the project.

Selecting a Gear-Motor that would be appropriate for your project could take many hours of research,

and, I don't know which suppliers are available to your location.

A much less powerful Motor, with gear-Reduction added,

will do the work that You are asking for.

( it looks like this is a Butter-Churn project )

Since You are wanting to reduce the physical-size of the Butter-Churn,

much less Power is required from the Motor, compared to the Churn that is in the video.

The RPM of the Churn must be kept very low to prevent splashing-out all of the Milk.

The Gear-Reduction will provide the additional Torque required

for when the mixture starts to get very thick and viscous.

You can't have too much Torque,

but You CAN DEFINITELY have too much RPM,

this is the reason for having the Gear-Reduction on the Motor.

This project is a lot of work, for a device that seems to have very limited increased-value

over the commercially available options.

If You want to go to the trouble to find, and purchase, an appropriate ~1000-RPM Gear-Motor,

I will provide You with a very versatile Automatic-Motor-Reversing, and Speed-Controlling-Circuit.

I will be waiting to see the selection of Gear-Motors that

You find that may be appropriate for this application.

Some will certainly be better suited to the job than others.

.

.

.

because I needed more information about the equipment that will actually be used in the project.

Selecting a Gear-Motor that would be appropriate for your project could take many hours of research,

and, I don't know which suppliers are available to your location.

A much less powerful Motor, with gear-Reduction added,

will do the work that You are asking for.

( it looks like this is a Butter-Churn project )

Since You are wanting to reduce the physical-size of the Butter-Churn,

much less Power is required from the Motor, compared to the Churn that is in the video.

The RPM of the Churn must be kept very low to prevent splashing-out all of the Milk.

The Gear-Reduction will provide the additional Torque required

for when the mixture starts to get very thick and viscous.

You can't have too much Torque,

but You CAN DEFINITELY have too much RPM,

this is the reason for having the Gear-Reduction on the Motor.

This project is a lot of work, for a device that seems to have very limited increased-value

over the commercially available options.

If You want to go to the trouble to find, and purchase, an appropriate ~1000-RPM Gear-Motor,

I will provide You with a very versatile Automatic-Motor-Reversing, and Speed-Controlling-Circuit.

I will be waiting to see the selection of Gear-Motors that

You find that may be appropriate for this application.

Some will certainly be better suited to the job than others.

.

.

.

ElectricSpidey

- Joined Dec 2, 2017

- 2,899

The schematic in post #2 needs some series resistors in line with those VRs to avoid some bad things.

MisterBill2

- Joined Jan 23, 2018

- 19,601

Many long years ago I did spend a few days on a farm where they had, and used, a hand cranked butter churn. Quite a bit bigger than the one in the picture. It is not likely that it would be spun even 100 RPM to successfully produce butter. So definitely an ultimate low speed is required. And probably just a series resistor will provide adequate setability.

My plan was to have a very-slow Triangle-Wave modulating a Full-Bridge PWM-Motor-Controller,

made with two 8-Amp-Continuous-Rated Gate-Driver ICs.

Zero-Volts from the Triangle-Wave equals Stop, plus or minus equals forward and reverse,

the amplitude of the Triangle-Wave would control the adjustable maximum speed.

This setup would be very versatile, and handle almost any small Gear-Motor with no sweat,

and a very low parts count.

But I think the TS may not realize all of the

mechanical-engineering that goes into making a project like this successful.

.

.

.

made with two 8-Amp-Continuous-Rated Gate-Driver ICs.

Zero-Volts from the Triangle-Wave equals Stop, plus or minus equals forward and reverse,

the amplitude of the Triangle-Wave would control the adjustable maximum speed.

This setup would be very versatile, and handle almost any small Gear-Motor with no sweat,

and a very low parts count.

But I think the TS may not realize all of the

mechanical-engineering that goes into making a project like this successful.

.

.

.

MisterBill2

- Joined Jan 23, 2018

- 19,601

Certainly the mechanical portion of an electrical/electronic product is often the challenge, as well as being the point of failure. Fortunately our design teams were able to communicate early enough so that most of the failures were on the pre-cad-design versions of the products. Pencil sketches are the best places to find design faults.

You May Also Like

-

Microchip’s New 32-bit MCUs Include Built-In Hardware Security Module

by Aaron Carman

-

A Q&A With GlobalFoundries’ Vikas Gupta: With Silicon Photonics, Data Centers Can Shoulder AI

-

Simulating MOSFET Current-Voltage Characteristics Using Advanced SPICE Models

by Robert Keim

-

New PC-Based 5 GS/s Oscilloscope First to Be Powered by USB

by Aaron Carman