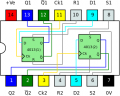

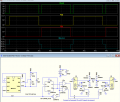

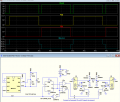

Below is the LTspice sim of a 555 circuit with two relays forming a bridge, that reverses the motor with off-time between reversals.

The motor (blue trace) has an off-time between reversals equal to the low period of the 555 (determined by the value of R2).

Edit: Changed output gates from AND to NOR to eliminate output glitches from a race condition.

The motor (blue trace) has an off-time between reversals equal to the low period of the 555 (determined by the value of R2).

Edit: Changed output gates from AND to NOR to eliminate output glitches from a race condition.

Last edited: