Right now I'm using a shopvac as a dust collector. I'd like to have something more suited to the task but I balk at paying $1k+ for a glorified vacuum cleaner with a sticker that says "dust collector."

Small vacuum motors can be had from surpluscenter for under $20. They resemble Ametek Lamb motors I have dealt with before. But looking at the specs on commercial dust collectors (2000+ CFM), it appears as though I'd need quite a few of those to make it work. Looking for other options...

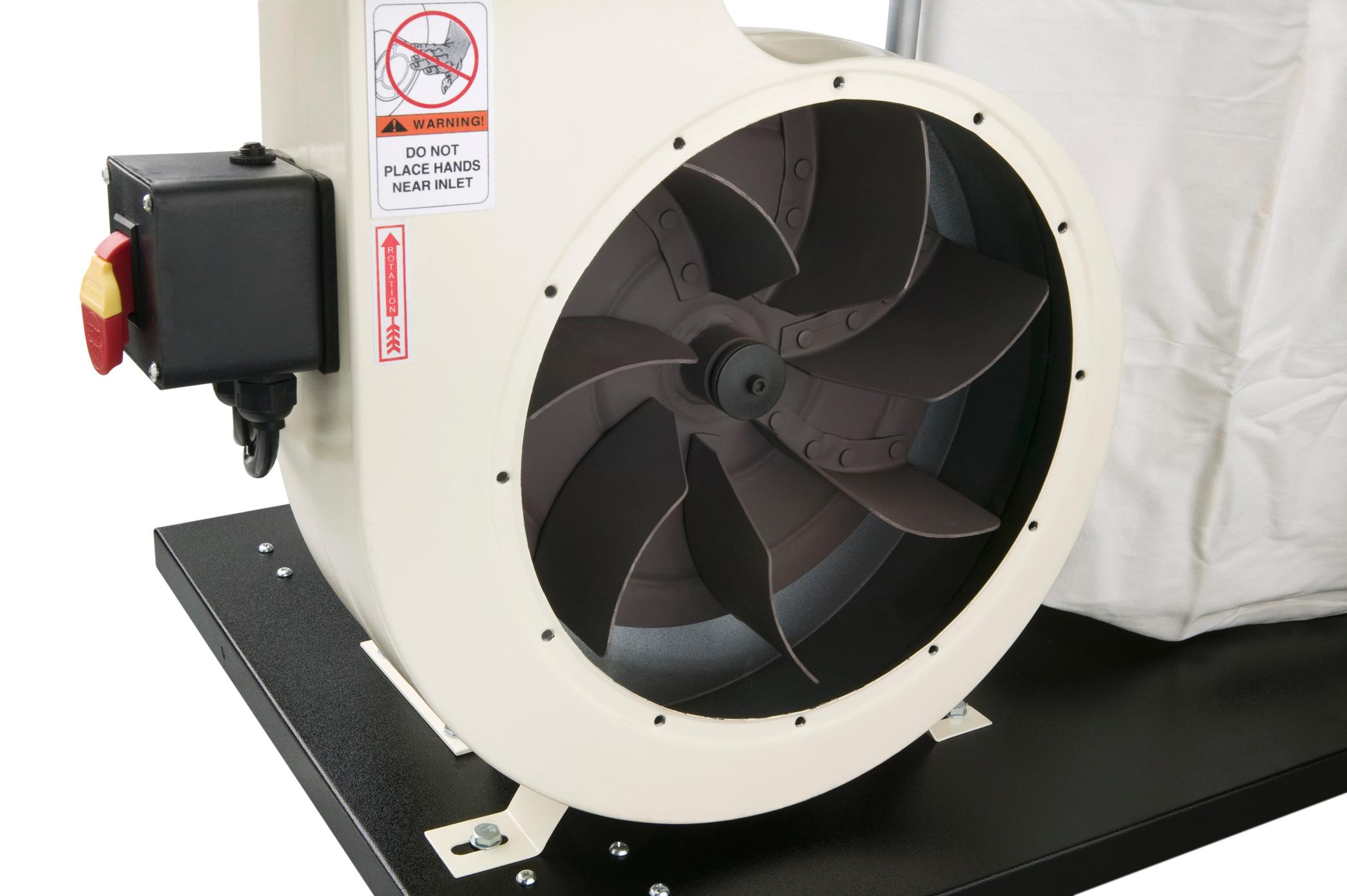

I ran across some aftermarket performance auto radiator fans rated over 1000CFM, for under $40. Just looking at CFM, I could hit the target with 2 radiator fans. But I'm not sure if CFM from a radial fan designed to blow, is an apples-to-apples comparison to CFM from a squirrel cage unit designed to suck.

One side of my head says that both are prime movers, whose job it is to move air from one place to another; suction and discharge are (must be) equal. Therefore 1000CFM is 1000CFM, no matter what. Then the other side of my head chimes in and says: yeahhbut... the squirrel cage suction unit has the outer duct/shroud to prevent "traction loss" (for lack of the proper term - air slipping past the blades instead of being moved forward by them). But I'm not sure that's true either, after seeing what happens when I block off the inlet of my shopvac.

Someone, please resolve my internal dispute.

Small vacuum motors can be had from surpluscenter for under $20. They resemble Ametek Lamb motors I have dealt with before. But looking at the specs on commercial dust collectors (2000+ CFM), it appears as though I'd need quite a few of those to make it work. Looking for other options...

I ran across some aftermarket performance auto radiator fans rated over 1000CFM, for under $40. Just looking at CFM, I could hit the target with 2 radiator fans. But I'm not sure if CFM from a radial fan designed to blow, is an apples-to-apples comparison to CFM from a squirrel cage unit designed to suck.

One side of my head says that both are prime movers, whose job it is to move air from one place to another; suction and discharge are (must be) equal. Therefore 1000CFM is 1000CFM, no matter what. Then the other side of my head chimes in and says: yeahhbut... the squirrel cage suction unit has the outer duct/shroud to prevent "traction loss" (for lack of the proper term - air slipping past the blades instead of being moved forward by them). But I'm not sure that's true either, after seeing what happens when I block off the inlet of my shopvac.

Someone, please resolve my internal dispute.