Forget about regenerative braking, guys!Eventually, yes. You would have to work up to that frequency from zero, to allow the rotor to accelerate. The Hall sensor, correctly positioned, would trigger a microcontroller to switch polarity. The devil is probably in the control detail. I imagine that, because of the rotary inertia, timing may depend on rpm, much as ignition timing needs advancing in a combustion engine. All that electronics in the Dyson appliance must be doing something more though (unless it's just there for obfuscation). Perhaps it's for regenerative braking and battery charging?

If my theory is correct about the angular offset of the rotor's rest position, I think applying say ~100mA DC in one polarity would be enough to cause the rotor to move just a few degrees in one direction; ~100mA DC in the other polarity (once the rotor had returned to its rest position) would move the rotor through nearly 180 degrees in the opposite direction.

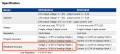

It require minimum 6.3A to pass from one position to the other, otherwise it is moving, but not able to complete the travel.

When connected to the current generator, I can see 0.52/0.63 V on the pins (at least these values was what appear in each channel of my power supply).

I am lucky that my power supply is capable of MAX 3.2A per channel.. Just at the limit to make the test using parallel mode.

With this milestone, we are already the first easily accessible resource that describes how to make it move!

As soon as I get equipped we will make it run!

Thanks everyone.

Ciao

PS: I forget to answer one point.

With 100mA, nothing happen; it's a hungry monster, I don't remember precisely (I didn't write it down) but it seems to me that it's already starting to move around 500-600mA - certainly with 1A.

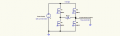

PS2: now that we redefine it as BLDC, I found this that seems to me very similar looking, at https://etheses.whiterose.ac.uk/21881/1/719808.pdf, page 81.

Last edited: