I need to switch a diesel heater that is the same type as Webasto or Eberspacher diesel powered air-heater for heating a small greenhouse.

The heater has a warm-up phase and a shut-down phase which is normally controlled by a single push-button being pressed to start or stop. It cannot be controlled simply by opening and closing the 12V power supply to the heater unit.

I can design the upper and lower thermostat switching but I need to have a circuit that gives a single pulse or shot to the button circuit on temperature rise and temperature fall.

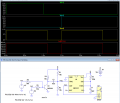

So if I have a 12V circuit that "makes on rise" and another circuit that "makes on fall" I need an interposed circuit for each switching operation that when given a 12V signal will close a switch momentarily for, say 1 second, that then simulates a switch press. The same logic for the " make on fall" operation.

Anyone? If this topic has already been covered then please accept my newbie apologies.

Zircon

The heater has a warm-up phase and a shut-down phase which is normally controlled by a single push-button being pressed to start or stop. It cannot be controlled simply by opening and closing the 12V power supply to the heater unit.

I can design the upper and lower thermostat switching but I need to have a circuit that gives a single pulse or shot to the button circuit on temperature rise and temperature fall.

So if I have a 12V circuit that "makes on rise" and another circuit that "makes on fall" I need an interposed circuit for each switching operation that when given a 12V signal will close a switch momentarily for, say 1 second, that then simulates a switch press. The same logic for the " make on fall" operation.

Anyone? If this topic has already been covered then please accept my newbie apologies.

Zircon