I am trying to fix it up an old 12 volt trolling motor for my son, and am stuck. Can someone help figure out what wire goes to what terminal?

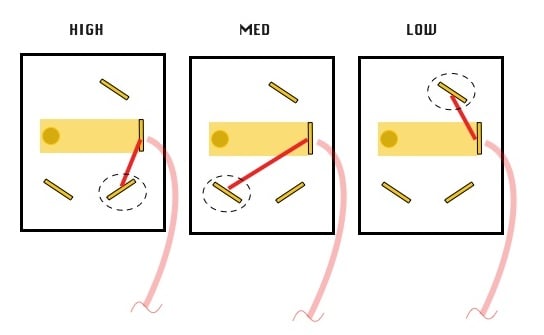

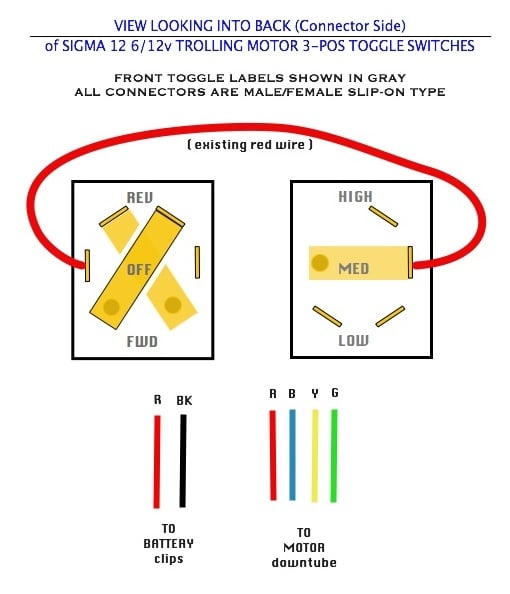

The unit just has two 3-position toggle switches for control; FWD-OFF-REV and HIGH-MED-LOW. I am pretty sure I understand the first switch, but it must be coupled with the second switch and the motor in such a way that I do not understand. Just do not want to fry anything by guessing.

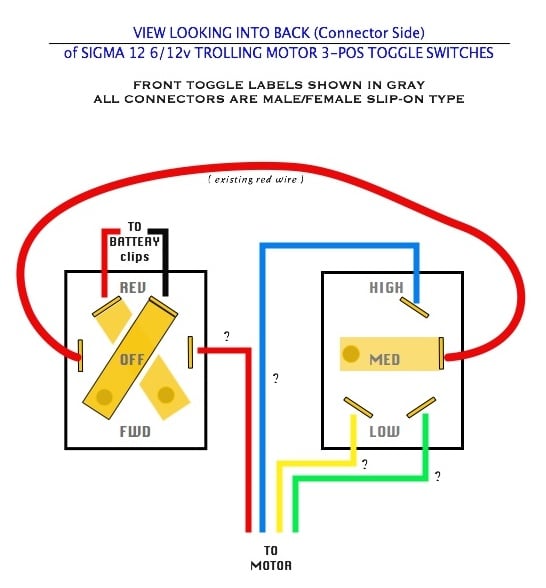

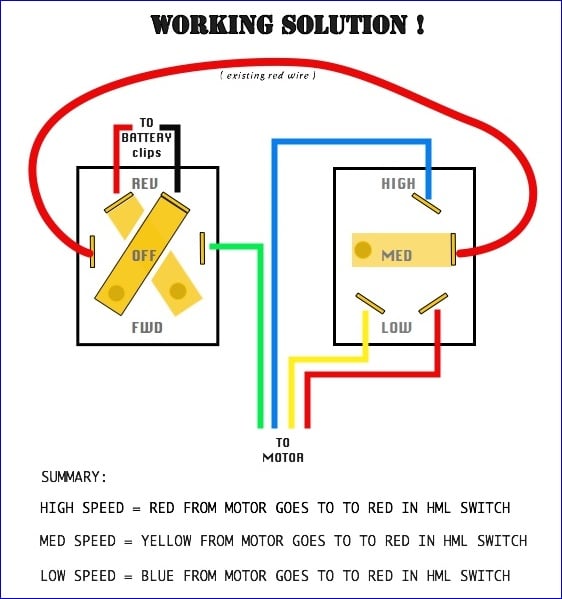

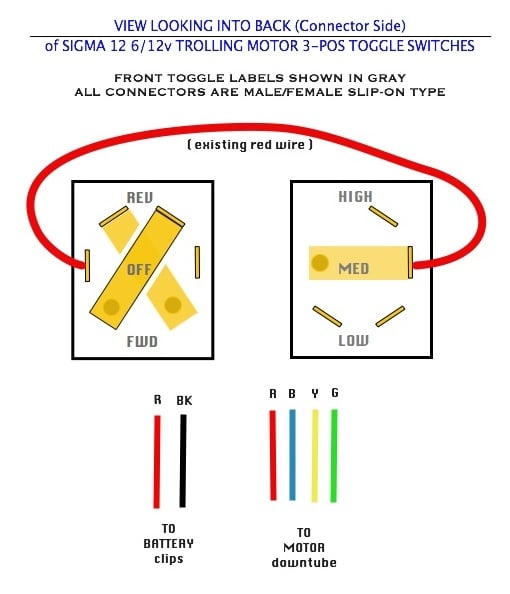

The FWD-OFF-REV switch has 3 unoccupied terminals, and the HIGH-MED-LOW switch also has 3 unoccupied terminals. Here is a sketch showing what I have:

The root cause of the problem (aside from my own lacking knowledge) is that someone has detatched all the wires from the back of the two switches, except for ONE red (power I presume) wire that ties the two switches together. There are two wires available from the battery clips, black and red. And there are four wires available from the DC motor, red blue yellow and green. I cannot see where these connect to the sealed motor; these 4 wires emerge from the downtube.

Does anyone know what wire goes to what terminal? After searching online for several days, and calling the current manufacturer (who surprisingly had no clue - citing product age as the problem), I hope someone in this great forum can help.

THANKS!

Phil

The unit just has two 3-position toggle switches for control; FWD-OFF-REV and HIGH-MED-LOW. I am pretty sure I understand the first switch, but it must be coupled with the second switch and the motor in such a way that I do not understand. Just do not want to fry anything by guessing.

The FWD-OFF-REV switch has 3 unoccupied terminals, and the HIGH-MED-LOW switch also has 3 unoccupied terminals. Here is a sketch showing what I have:

The root cause of the problem (aside from my own lacking knowledge) is that someone has detatched all the wires from the back of the two switches, except for ONE red (power I presume) wire that ties the two switches together. There are two wires available from the battery clips, black and red. And there are four wires available from the DC motor, red blue yellow and green. I cannot see where these connect to the sealed motor; these 4 wires emerge from the downtube.

Does anyone know what wire goes to what terminal? After searching online for several days, and calling the current manufacturer (who surprisingly had no clue - citing product age as the problem), I hope someone in this great forum can help.

THANKS!

Phil