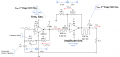

After my last thread, I realised many things (thanks to all who contributed), updated my drawings accordingly, and am asking for guidance as to the component design I should use as a start in the design process. It is small circuit, and I've had some setbacks in engaging local designers, so I am attempting to design it myself. The circuit is shown below: