Hi guys this is the second conversation I am starting on this forum,

I previously asked questions about why my mosfets kept blowing up when driving my outboard motor. Now I think I understood better I am now wondering how to properly choose your mosfet driver IC.

Here is the motor I want to drive : E30-150-24 https://www.ampflow.com/motors/highPerformance/threeInch/#economy

Here are the mosfets I'll be using : P75NF75 https://pdf1.alldatasheet.com/datasheet-pdf/download/999561/THINKISEMI/P75NF75.html

I want to drive my motor with a maximum current of around 80A and I am planning on paralleling 4 mosfets on the same heat sink to reduce conduction losses even though the the switching losses might increase a bit.

I am using a homemade 7S13P battery pack so Vbat [25,2-29,4V] and a 80A BMS, for my motor controller I planned on using a Buck converter to convert my battery voltage to a lower stable voltage lets say 15V, this 15V will be used to power my 555 timer for the PWM output and the mosfet driver ic or directly from Vbat ( I don't know which is best).

For my PWM signal input I am using a 555 timer with a frequency of around 1kHz (maybe it is too low ? we will see...)

For the driver I was not decided between these 2:

https://www.mouser.fr/datasheet/2/268/MCHPS05700_1-2520587.pdf

https://www.infineon.com/dgdl/Infin...5ddCNnXxUBZj6dHT8N0aAvBTEALw_wcB&gclsrc=aw.ds

I know the first one can source up to 12A so I think I will be ok to drive my 4 mosfets fast enough with a low gate resistance (around 5-10 ohms)

The second one can source/sink (+4A/-8A) which I don't think is high enough source current in order to drive my mosfet fast enough?

The problem I had before was that I used the 555timer to directly drive my 4 IRFZ44 mosfets which all had 100ohm gate resistant (I know really badly scaled but this is my first electronics project I'm a chemical engineer ahah so I'm still learning a lot thanks to youtube and you guys ) my mosfets kept blowing up and i didn't understand why. Now I know that I need to switch them on/off faster in order to lower the Resistance when startup and falldown so I have less switching losses and less heating up.

so I'm still learning a lot thanks to youtube and you guys ) my mosfets kept blowing up and i didn't understand why. Now I know that I need to switch them on/off faster in order to lower the Resistance when startup and falldown so I have less switching losses and less heating up.

Now my real question is, what is an optimal turn on time + rise time (and same for the fall time ) because I have no order of magnitude.

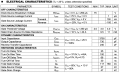

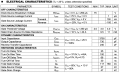

For reference these are some of the mosfets specs :

So if let's say I have 1A driver current into each mosfet with a Qg=160nC (max) that means my turn on delay time+rise time= Qg/1A= 160ns. But in order to have 1A flowing out of my driver and for Vgs=10V(arbitrary and potentially the maximum) that means that Rg=10V/1A=10ohm right ?

But also how do I know what Vgs I need in order to have 20Amps flowing through one mosfet ?

If you need more information please tell me.

And thank you all in advance

Cheers

Timothee

I previously asked questions about why my mosfets kept blowing up when driving my outboard motor. Now I think I understood better I am now wondering how to properly choose your mosfet driver IC.

Here is the motor I want to drive : E30-150-24 https://www.ampflow.com/motors/highPerformance/threeInch/#economy

Here are the mosfets I'll be using : P75NF75 https://pdf1.alldatasheet.com/datasheet-pdf/download/999561/THINKISEMI/P75NF75.html

I want to drive my motor with a maximum current of around 80A and I am planning on paralleling 4 mosfets on the same heat sink to reduce conduction losses even though the the switching losses might increase a bit.

I am using a homemade 7S13P battery pack so Vbat [25,2-29,4V] and a 80A BMS, for my motor controller I planned on using a Buck converter to convert my battery voltage to a lower stable voltage lets say 15V, this 15V will be used to power my 555 timer for the PWM output and the mosfet driver ic or directly from Vbat ( I don't know which is best).

For my PWM signal input I am using a 555 timer with a frequency of around 1kHz (maybe it is too low ? we will see...)

For the driver I was not decided between these 2:

https://www.mouser.fr/datasheet/2/268/MCHPS05700_1-2520587.pdf

https://www.infineon.com/dgdl/Infin...5ddCNnXxUBZj6dHT8N0aAvBTEALw_wcB&gclsrc=aw.ds

I know the first one can source up to 12A so I think I will be ok to drive my 4 mosfets fast enough with a low gate resistance (around 5-10 ohms)

The second one can source/sink (+4A/-8A) which I don't think is high enough source current in order to drive my mosfet fast enough?

The problem I had before was that I used the 555timer to directly drive my 4 IRFZ44 mosfets which all had 100ohm gate resistant (I know really badly scaled but this is my first electronics project I'm a chemical engineer ahah

Now my real question is, what is an optimal turn on time + rise time (and same for the fall time ) because I have no order of magnitude.

For reference these are some of the mosfets specs :

So if let's say I have 1A driver current into each mosfet with a Qg=160nC (max) that means my turn on delay time+rise time= Qg/1A= 160ns. But in order to have 1A flowing out of my driver and for Vgs=10V(arbitrary and potentially the maximum) that means that Rg=10V/1A=10ohm right ?

But also how do I know what Vgs I need in order to have 20Amps flowing through one mosfet ?

If you need more information please tell me.

And thank you all in advance

Cheers

Timothee

Last edited: