Hi all,

Somewhat new to electronics. I studied mechanical engineering and learned a lot of electronic principles in some EE courses but very little hands on application outside of solving drawn circuits.

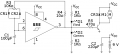

I am trying to build a speed controller using the following circuit with a CMOS 555 timer for power conservation:

I don’t have a potentiometer so I wired pin 7 directly the node between Ra and Rb. I also don’t have a 10nf cap so I am using a 100nf off of pin 5.

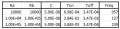

Instead, I tested the model with the following R values:

1)

Ra = 10K

Rb = 10K

C = 50nF

2)

Ra = 10K

Rb = 100K

C = 50nF

3)

Ra = 100k

Rb = 10k

C = 50nF

For some reason all 3 of these setups are resulting in the same RPM/motor voltage drop of 2.5V when providing a 3.3V power supply.

Circuit link:

https://www.electronics-tutorials.ws/blog/pulse-width-modulation.html

Can anyone see a problem with the circuit design/ a reason why changing these values is not changing the motor speed/voltage drop?

My end goal is a specified RPM, so if omitting the pot is my problem, how can I set the circuit up once the R values are defined to omit the pot for a constant specified motor speed?

Thank you!!

Sophia

Somewhat new to electronics. I studied mechanical engineering and learned a lot of electronic principles in some EE courses but very little hands on application outside of solving drawn circuits.

I am trying to build a speed controller using the following circuit with a CMOS 555 timer for power conservation:

I don’t have a potentiometer so I wired pin 7 directly the node between Ra and Rb. I also don’t have a 10nf cap so I am using a 100nf off of pin 5.

Instead, I tested the model with the following R values:

1)

Ra = 10K

Rb = 10K

C = 50nF

2)

Ra = 10K

Rb = 100K

C = 50nF

3)

Ra = 100k

Rb = 10k

C = 50nF

For some reason all 3 of these setups are resulting in the same RPM/motor voltage drop of 2.5V when providing a 3.3V power supply.

Circuit link:

https://www.electronics-tutorials.ws/blog/pulse-width-modulation.html

Can anyone see a problem with the circuit design/ a reason why changing these values is not changing the motor speed/voltage drop?

My end goal is a specified RPM, so if omitting the pot is my problem, how can I set the circuit up once the R values are defined to omit the pot for a constant specified motor speed?

Thank you!!

Sophia