I will start with the fact that I have little to know knowledge of building circuits. I am in fact looking for someone that is willing to essentially draw me a wiring diagram and even better list of parts needed.

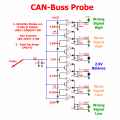

I am building a breakout box for an automotive OBD2 DLC. What I am wanting to do is make a visual indicator of voltage presence on can and lin busses. The idea is if there is no voltage I can wiggle harnesses and see it "turn on" or alternatively un plug a module and see the buss come on. Any actual testing of what is on the network will be done with a lab scope. I am hoping to have an LED for each pin of the DLC to watch for activity. I am not even against just having an led that is on when there is voltage present or if it is possible just on when voltage is between 1 and 5 volts. I would assume that what is used for can high and can low can be adapted for lin bus just need to change voltage levels, but as I said I have very little knowledge of the building of circuits.

Thank you for any help.

I am building a breakout box for an automotive OBD2 DLC. What I am wanting to do is make a visual indicator of voltage presence on can and lin busses. The idea is if there is no voltage I can wiggle harnesses and see it "turn on" or alternatively un plug a module and see the buss come on. Any actual testing of what is on the network will be done with a lab scope. I am hoping to have an LED for each pin of the DLC to watch for activity. I am not even against just having an led that is on when there is voltage present or if it is possible just on when voltage is between 1 and 5 volts. I would assume that what is used for can high and can low can be adapted for lin bus just need to change voltage levels, but as I said I have very little knowledge of the building of circuits.

Thank you for any help.