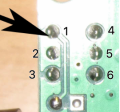

I am wiring a controller to a stepper motor. The controller has a forward/reverse button which is a press button, press once for forward and press again for reverse. I want to change it to a three way rocker switch which has 6 terminals in three pairs which means making the press button redundant and wiring in the rocker. I know how to wire the rocker switch from Youtube. My problem is I know nothing about electronics. I have attached two photos of the controller one showing the top and the other the circuitry on the reverse side.. The forward/reverse button is at the upper right and on the other side are the 6 soldered terminals at the upper left. I think I need to wire the rocker into those 6 terminals but I do notknow what needs to go where. I have seen a video of this which appears to show 2 wires from the rocker going to the middle two terminals on the controller but the other two wires are not clear to see.

Any advice will be greatly appreciated.

Attachments

Any advice will be greatly appreciated.

Attachments

FT VOGUE Controller.jpg

218 KB Views: 9

Stepper-motor-controller.jpg

2.9 MB Views: 8