Hi everybody, guess the electronic bug has bit me again and would like to embark on a group project with my engine crew

Sometimes we need a pressure transmitter that can show pressures up to 400 bar (5800 Psi) These (the displays./readers.) are very expensive and rarely used. So I was thinking it be fun to make one. Precision just has to be close enough, without the project becoming a moon rocket. The intent is to make a handheld display with 9V battery(s). The battery time does not have to be several hours.

I found a few parts, and jumped the gun on buying a Schnider XMEP400BD21F Pressure transmitter 400 bar G1/4A 4-20mA M12 (12-24 VDC supply)

But later I found out, that this will not be an easy task to feed to an ADC, since most of them run on volts. And it has to be supplied with at least 12VDC.

One that would fit perfect is the XMEP400BD11F Pressure transmitter 400 bar G1/4A 0.5-4.5V M12 (5V supply), given it's low voltage. But the reason for buying the 20 mA one was precision, and that 4-20 mA signals are widely used on ships with great success. A range of 4V to cover 400 bars sounds like a difficult task for the transducer element.

And there is also the XMEP400BD71F Pressure transmitter 400 bar G1/4A 0-10V M12 (24 VDC supply)

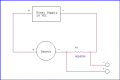

Going with the 4-20 mA version, I added this to my shopping cart:

- MCP3301-BI/P (13 bit ADC)

- MCP1541-I/TO (Voltage ref)

- PIC16F1783-I/SP (Compatible with my Microchip HPC board. Also have a few others laying around)

- 2 line LCD

- LM7805CT (5V regulator)

- RCV420JP (Have not added this yet, but read that this could be used for converting 4-20 mA signal to volts. Can see the output is 0-5V...hmm...)

- 2 meter M12 plug wire

- Plugs, op-amps, resistors, caps...

Now the questions:

With all this stuff, do I have the parts need to build this pressure reader?

Which is the best route, the 4-20 mA or the 0.5-4.5V transmitter build? Guess the 4.5V build would be helluva lot easier.

Is a range of 4-5 volts enough to cover such a large range as 400bar/5800 Psi?

Datasheets for transmitters (in Danish..)

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD11F&scp_id=DK_da

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD21F&scp_id=DK_da

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD71F&scp_id=DK_da

Sometimes we need a pressure transmitter that can show pressures up to 400 bar (5800 Psi) These (the displays./readers.) are very expensive and rarely used. So I was thinking it be fun to make one. Precision just has to be close enough, without the project becoming a moon rocket. The intent is to make a handheld display with 9V battery(s). The battery time does not have to be several hours.

I found a few parts, and jumped the gun on buying a Schnider XMEP400BD21F Pressure transmitter 400 bar G1/4A 4-20mA M12 (12-24 VDC supply)

But later I found out, that this will not be an easy task to feed to an ADC, since most of them run on volts. And it has to be supplied with at least 12VDC.

One that would fit perfect is the XMEP400BD11F Pressure transmitter 400 bar G1/4A 0.5-4.5V M12 (5V supply), given it's low voltage. But the reason for buying the 20 mA one was precision, and that 4-20 mA signals are widely used on ships with great success. A range of 4V to cover 400 bars sounds like a difficult task for the transducer element.

And there is also the XMEP400BD71F Pressure transmitter 400 bar G1/4A 0-10V M12 (24 VDC supply)

Going with the 4-20 mA version, I added this to my shopping cart:

- MCP3301-BI/P (13 bit ADC)

- MCP1541-I/TO (Voltage ref)

- PIC16F1783-I/SP (Compatible with my Microchip HPC board. Also have a few others laying around)

- 2 line LCD

- LM7805CT (5V regulator)

- RCV420JP (Have not added this yet, but read that this could be used for converting 4-20 mA signal to volts. Can see the output is 0-5V...hmm...)

- 2 meter M12 plug wire

- Plugs, op-amps, resistors, caps...

Now the questions:

With all this stuff, do I have the parts need to build this pressure reader?

Which is the best route, the 4-20 mA or the 0.5-4.5V transmitter build? Guess the 4.5V build would be helluva lot easier.

Is a range of 4-5 volts enough to cover such a large range as 400bar/5800 Psi?

Datasheets for transmitters (in Danish..)

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD11F&scp_id=DK_da

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD21F&scp_id=DK_da

https://www.ops-ecat.schneider-elec...ist_Id=scope&prd_id=XMEP400BD71F&scp_id=DK_da