Hello everyone! Over the past 5 years I have been restoring a very worse for wear McIntosh C20 Tube Preamplifier. The build is complete and looking beautiful (I documented it fully on a major audio forum) and along the way I build some replacement parts for it, as they are mostly unavailable given the age of the machine (1959-1963). I am currently designing and building a replacement volume potentiometer which has an integrated power switch as these are known to go bad on McIntosh's and whilst replacements are available on the auction site (I bought one and its been great), many people complain about the quality of them. A wonderful option is available from Gold Point, but it requires modification to the C20 which I am trying to avoid with mine.

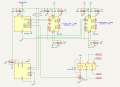

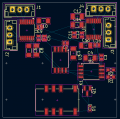

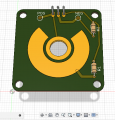

Here is my plan: 4 audio PCB's and a power PCB at the rear

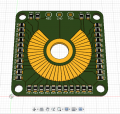

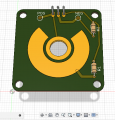

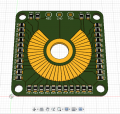

This is my design for the audio PCB. A 37 segment stepped attenuator that will use a potentiometer wiper to make the selections:

I am really comfortable with the design of the audio PCB's, but I would really like some support on the PCB for the power switch as its much more dangerous if I get it wrong, plus I cannot risk damaging my C20 if I happen to mess it up. I am one of those people who knows enough to be dangerous, so I would prefer to progress with significant caution.

I am effectively trying to replace a rotary switch which takes up a lot of travel of the volume pot (25%) and turn it in to a 7.5 degree switch. My plan was to try and use a triac to do the switching and a voltage divider circuit to drop down the voltage and current to allow me to use the same type of potentiometer wiper/track circuitry to activate the gate. However because its driving an inductive load, I am now also considering adding in a snubber circuit for safety on the triac side too.

I used some simulation software to see if the voltage and current would be ok to put on a potentiometer wiper track and got something so low, that it appeared fine. But I am keen to triple check my thinking here is correct. Plus I am keen to understand if my plans to put all of this on a PCB (40mm x 40mm) will work for the application (eg heat from the triac, ensuring I can manage electrical noise in a preamp).

1. Can I use a potentiometer wiper and hard gold track to activate a triac gate

C20 is on 117v and uses 35w of power

I was reading the voltage and current on the switch as:

Switch voltage: 740 mv

Switch current: 70 uA

Gate voltage: 11 mv

Gate current: 62 uA

Do I have this correct? This would suggest to me that my concept to use a potentiometer wiper to activate the gate will work.

I am trying to package everything together on a PCB as tightly as I can. What do I need to consider in the PCB design to ensure it will work reliably, safety and effectively? Currently I have designed thicker than required tracks for all connections as a safety margin and I am finalising the new PBC design at the moment that I would love to get some feedback on too, to make sure I have not made any fatal errors.

Here is my plan: 4 audio PCB's and a power PCB at the rear

This is my design for the audio PCB. A 37 segment stepped attenuator that will use a potentiometer wiper to make the selections:

I am really comfortable with the design of the audio PCB's, but I would really like some support on the PCB for the power switch as its much more dangerous if I get it wrong, plus I cannot risk damaging my C20 if I happen to mess it up. I am one of those people who knows enough to be dangerous, so I would prefer to progress with significant caution.

I am effectively trying to replace a rotary switch which takes up a lot of travel of the volume pot (25%) and turn it in to a 7.5 degree switch. My plan was to try and use a triac to do the switching and a voltage divider circuit to drop down the voltage and current to allow me to use the same type of potentiometer wiper/track circuitry to activate the gate. However because its driving an inductive load, I am now also considering adding in a snubber circuit for safety on the triac side too.

I used some simulation software to see if the voltage and current would be ok to put on a potentiometer wiper track and got something so low, that it appeared fine. But I am keen to triple check my thinking here is correct. Plus I am keen to understand if my plans to put all of this on a PCB (40mm x 40mm) will work for the application (eg heat from the triac, ensuring I can manage electrical noise in a preamp).

1. Can I use a potentiometer wiper and hard gold track to activate a triac gate

C20 is on 117v and uses 35w of power

I was reading the voltage and current on the switch as:

Switch voltage: 740 mv

Switch current: 70 uA

Gate voltage: 11 mv

Gate current: 62 uA

Do I have this correct? This would suggest to me that my concept to use a potentiometer wiper to activate the gate will work.

I am trying to package everything together on a PCB as tightly as I can. What do I need to consider in the PCB design to ensure it will work reliably, safety and effectively? Currently I have designed thicker than required tracks for all connections as a safety margin and I am finalising the new PBC design at the moment that I would love to get some feedback on too, to make sure I have not made any fatal errors.