Hello!

I am about to embark on a small project to build a star tracking platform for my camera, and I would greatly appreciate a little help regarding the circuit design and component sourcing.

I am new to electronics and have not built anything outside of school projects may years ago, but I like to see myself as a hands on techy person :geek: and I have a soldering iron!

What I am trying to achieve is to build a circuit which would control a motor to turn at precisely 1rpm. This could be done via the circuit controlling the motor directly to 1rpm or by having a precise alternate rpm from the motor and then using small gears to give a resultant 1rpm.

There are various designs online for such circuits, but a lot of them are different and a either way I dont think I would stand a chance without some advice. Here is a design for a similar star tracking platform which will help anyone interested see what my end goal is:

http://www.garyseronik.com/?q=node/52

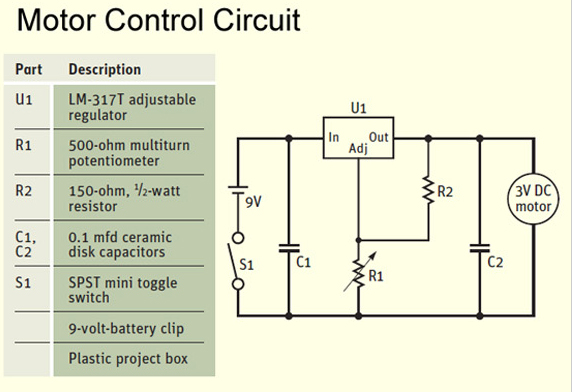

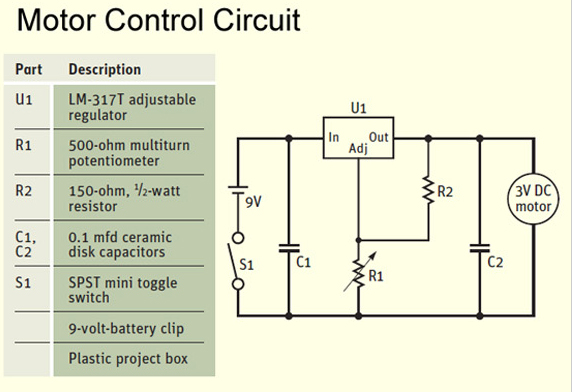

There is a circuit design at the bottom of the web page:

This diagram is by no means strictly what I want to go with, I have no idea if this is the best way to go about it so I would love to hear some ideas and would really appreciate some advice.

Another problem is I have no idea how to source this kind of stuff, so advice on shops or a good website to get components from would help. I am based in London UK.

Thanks in advance!

Dan

I am about to embark on a small project to build a star tracking platform for my camera, and I would greatly appreciate a little help regarding the circuit design and component sourcing.

I am new to electronics and have not built anything outside of school projects may years ago, but I like to see myself as a hands on techy person :geek: and I have a soldering iron!

What I am trying to achieve is to build a circuit which would control a motor to turn at precisely 1rpm. This could be done via the circuit controlling the motor directly to 1rpm or by having a precise alternate rpm from the motor and then using small gears to give a resultant 1rpm.

There are various designs online for such circuits, but a lot of them are different and a either way I dont think I would stand a chance without some advice. Here is a design for a similar star tracking platform which will help anyone interested see what my end goal is:

http://www.garyseronik.com/?q=node/52

There is a circuit design at the bottom of the web page:

This diagram is by no means strictly what I want to go with, I have no idea if this is the best way to go about it so I would love to hear some ideas and would really appreciate some advice.

Another problem is I have no idea how to source this kind of stuff, so advice on shops or a good website to get components from would help. I am based in London UK.

Thanks in advance!

Dan