Hey, everyone!

I am working on designing my own circuit and had some questions on typical procedure.

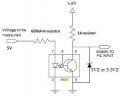

At work I use an Arduino PLC called the Controllino which operates at 12V *OR* 24V logic, either works, and no settings need to be changed. I wanted to design something similar using an Atmega328p, which of course, runs on 5V logic. Ideally, I need mine to operate at 12/24V just as the Controllino does. Upon doing my research (self-taught EE and hobbyist), I can figure out several different ways to step down EITHER 12V or 24V separately using voltage dividers, regulators, or a resistor/diode network, but can't seem to figure out how a single circuit can operate automatically at one or the other.

Basically, I know how to step down voltage to 5V but can't figure out how the input voltage can be 12V or 24V without using separate circuits. I hope this makes sense. Can anyone shed some light?

Thanks in advance!

I am working on designing my own circuit and had some questions on typical procedure.

At work I use an Arduino PLC called the Controllino which operates at 12V *OR* 24V logic, either works, and no settings need to be changed. I wanted to design something similar using an Atmega328p, which of course, runs on 5V logic. Ideally, I need mine to operate at 12/24V just as the Controllino does. Upon doing my research (self-taught EE and hobbyist), I can figure out several different ways to step down EITHER 12V or 24V separately using voltage dividers, regulators, or a resistor/diode network, but can't seem to figure out how a single circuit can operate automatically at one or the other.

Basically, I know how to step down voltage to 5V but can't figure out how the input voltage can be 12V or 24V without using separate circuits. I hope this makes sense. Can anyone shed some light?

Thanks in advance!