Hello forum, I don't remember the last time I posted here.

I have a boat with a V8 engine that I have rebuilt. The revcounter is supposedly switchable to be able to work with 2, 4, 6 and (I believe) 8 cylinder engines. The problem is that the revcounter seems not to work properly when set to what I believe is the 8 cylinder setting. It will work when set to the 4 cylinder setting but of course using the 4 cylinder setting with the 8 cylinder engine means the revcounter reads exactly double actual rpm. This is a problem because the engine redline is 4800rpm and the revcounter only reads up to 6000rpm, so above 3000rpm the revcounter goes off scale and could be damaged by literally bending the needle.

I could buy a gizmo from Amazon that will convert the 8 cylinder engine ignition pulses to work with the revcounter set to 4 cylinders for around £30. The gizmo has dip switches and can be set to convert the tach signal from an engine with just about any number of cylinders to work with any rev counter, but I hope someone on this forum can show me a simple electronics circuit that will do what I need.

Nearly forgot to mention, the boat engine has a conventional old-skool sparks distributor with only one ignition coil and for intents and purposes I believe the ignition system could be considered a points style setup, though it is actually electronic inside the distributor.

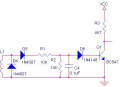

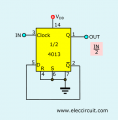

All the unit has to do is output 1 pulse to the tacho/revcounter for every 2 ignition pulses (from the negative pulsing side of the ignition coil). I could probably look at other threads (I did check to see if this subject had been covered before) and find a similar circuit to one I'm after, could even maybe design one myself, but I'm not sure about aspects such as whether de-bouncing (for want of a better term) would be necessary for the signal from the ignition coil, or making the circuit to withstand any high voltage pulses from the coil negative (though I suspect this might just involve a high value resistor and a small capacitor)...

Can anyone help please?

I have a boat with a V8 engine that I have rebuilt. The revcounter is supposedly switchable to be able to work with 2, 4, 6 and (I believe) 8 cylinder engines. The problem is that the revcounter seems not to work properly when set to what I believe is the 8 cylinder setting. It will work when set to the 4 cylinder setting but of course using the 4 cylinder setting with the 8 cylinder engine means the revcounter reads exactly double actual rpm. This is a problem because the engine redline is 4800rpm and the revcounter only reads up to 6000rpm, so above 3000rpm the revcounter goes off scale and could be damaged by literally bending the needle.

I could buy a gizmo from Amazon that will convert the 8 cylinder engine ignition pulses to work with the revcounter set to 4 cylinders for around £30. The gizmo has dip switches and can be set to convert the tach signal from an engine with just about any number of cylinders to work with any rev counter, but I hope someone on this forum can show me a simple electronics circuit that will do what I need.

Nearly forgot to mention, the boat engine has a conventional old-skool sparks distributor with only one ignition coil and for intents and purposes I believe the ignition system could be considered a points style setup, though it is actually electronic inside the distributor.

All the unit has to do is output 1 pulse to the tacho/revcounter for every 2 ignition pulses (from the negative pulsing side of the ignition coil). I could probably look at other threads (I did check to see if this subject had been covered before) and find a similar circuit to one I'm after, could even maybe design one myself, but I'm not sure about aspects such as whether de-bouncing (for want of a better term) would be necessary for the signal from the ignition coil, or making the circuit to withstand any high voltage pulses from the coil negative (though I suspect this might just involve a high value resistor and a small capacitor)...

Can anyone help please?

Last edited: