I'm new to Arduino and need some advice.

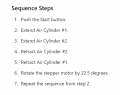

I have a small machine with 2 pneumatic cylinders, 1 stepper motor, 4 limit switches on the cylinders, a Door switch, and a couple of push buttons (start, stop etc).

Anyone got a recommendation for an Arduino controller?

I have a small machine with 2 pneumatic cylinders, 1 stepper motor, 4 limit switches on the cylinders, a Door switch, and a couple of push buttons (start, stop etc).

Anyone got a recommendation for an Arduino controller?