Speaking for now only of 50/60Hz toroidal power transformers, would there be any electrical difference between a transformer made from a core of rolled up strip (typical) or one made from stacked stamped laminations?

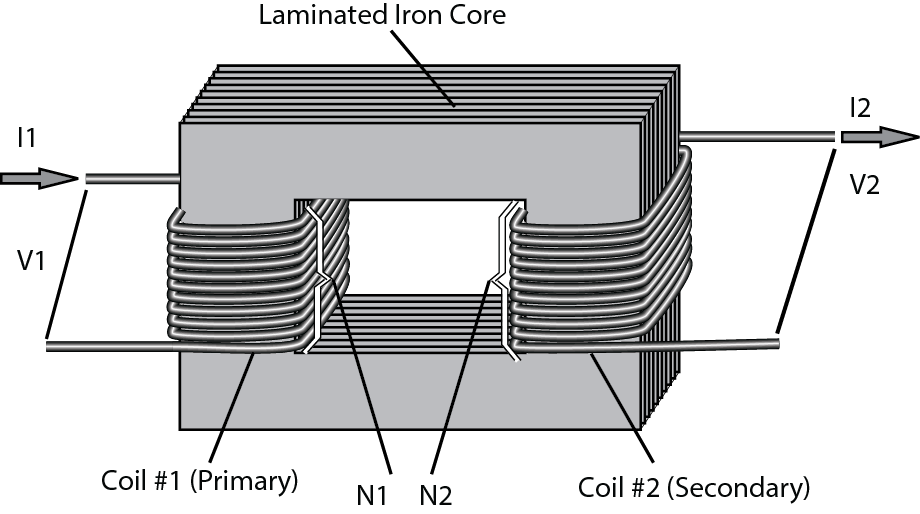

THIS (except a round version):

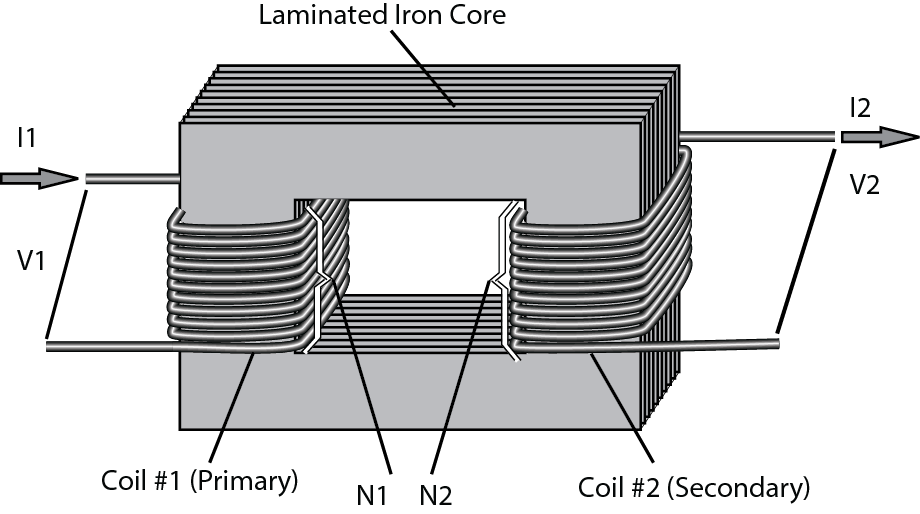

versus THIS:

???

I realize it would be a lot easier to make one from a rolled strip, but assuming you didn't have a roll of electrical steel to wind up, and for some reason you DID have a stack of (apparently nonexistent) circular laminations, would your stacked transformer core perform any differently than a rolled-up one of the exact same dimensions?

THIS (except a round version):

versus THIS:

???

I realize it would be a lot easier to make one from a rolled strip, but assuming you didn't have a roll of electrical steel to wind up, and for some reason you DID have a stack of (apparently nonexistent) circular laminations, would your stacked transformer core perform any differently than a rolled-up one of the exact same dimensions?