I have a refrigeration unit powered by a Danfoss compressor unit.

The compressor has the ability to operate at variable speeds via a variance of resistance in the thermostat circuit eg. at 1523 ohms .... 3500 rpm whereas at 0 ohms ...... 2000 rpm.

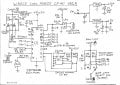

After market add-on's by third party manufactures have allowed consumers to manually change the resister settings to match optimized running conditions or have produced a timing circuit as shown below to 'automate' the change of speed dependent of running time.

The question I ask is what circuits would be appropriate for this operation based on variable times and speed change (resistance dependent) ?

Any thoughts would be appreciated.

Cheers... Bjorn

The compressor has the ability to operate at variable speeds via a variance of resistance in the thermostat circuit eg. at 1523 ohms .... 3500 rpm whereas at 0 ohms ...... 2000 rpm.

After market add-on's by third party manufactures have allowed consumers to manually change the resister settings to match optimized running conditions or have produced a timing circuit as shown below to 'automate' the change of speed dependent of running time.

The question I ask is what circuits would be appropriate for this operation based on variable times and speed change (resistance dependent) ?

Any thoughts would be appreciated.

Cheers... Bjorn