Hi, this is my first post.

I have an old sailing boat with BMW D12 marine diesel. The engine has a generator (or magneto) with brushless permanent magnet rotor and stator with coils. The problem is the rectifier/regulator that blows up about after three years usage. The part costs 200 and it's hard to find thanks to the engine's old model. I have planned to make it myself.

The rectifier/regulator parts are in a small aluminium heat sink box filled with epoxy. It's impossible to fix or even identify the components. I have find the circuit from the engine's workshop manual. The components are shown without values. The generator's charging capacity is 14 V 350 W - 25 Amps.

Can someone kindly help me to find right components for the rectifier/regulator? I have not very good skills in planning electronics but I can make and solver the unit myself if I get some help with finding components.

Magneto rectifier regulator circuit:

Stator AC output voltage between different wire pairs and rpms:

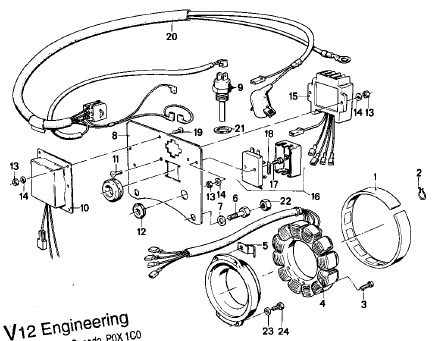

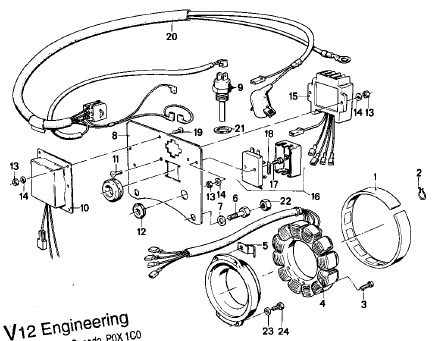

Original BMW electric diagram:

Picture of the stator:

Charging components, a picture from the workshop manual. The rectifier/regulator is number 15

I have an old sailing boat with BMW D12 marine diesel. The engine has a generator (or magneto) with brushless permanent magnet rotor and stator with coils. The problem is the rectifier/regulator that blows up about after three years usage. The part costs 200 and it's hard to find thanks to the engine's old model. I have planned to make it myself.

The rectifier/regulator parts are in a small aluminium heat sink box filled with epoxy. It's impossible to fix or even identify the components. I have find the circuit from the engine's workshop manual. The components are shown without values. The generator's charging capacity is 14 V 350 W - 25 Amps.

Can someone kindly help me to find right components for the rectifier/regulator? I have not very good skills in planning electronics but I can make and solver the unit myself if I get some help with finding components.

Magneto rectifier regulator circuit:

Stator AC output voltage between different wire pairs and rpms:

Original BMW electric diagram:

Picture of the stator:

Charging components, a picture from the workshop manual. The rectifier/regulator is number 15